-

Manufacturer: Pepperl+Fuchs

-

Product no. : FVM58N-011AEA3GN-0813

-

Product type : Multiturn absolute encoder

-

Data format : F = Fast parallel

-

Shaft version : V = Solid shaft

-

Principle of operation : M = Multiturn

-

Housing material : N = Aluminium, powder coated

-

Shaft dimension/flange version : 011 = Shaft ÿ10 mm x 20 mm with clamping flange

-

Connection type : AE = Plug connector type 9426, 26-pin (only axial)

-

Exit position : A = Axial

-

Option 1 : 3 = V/R, LATCH, PRESET

-

Output code : G = Gray

-

Option 2 : N = Not expanded

-

Number of bits multiturn (Revolutions) : 12 = 4096 (only connection type K2)

-

Number of bits singleturn (Resolution) : 08 = 256

-

Shipping Weight : 2 KG

IMCOS-7011-V2 PA/GA Remote control panel for desk with handheld or gooseneck microphone

- The panel includes:

• 25 pushbuttons illuminated polycarbonate keypad;

• microphone with push to talk feature;

• 1 illuminated emergency call pushbutton;

• 1 dimmer for polycarbonate keyboard light;

• 1 volume control for external loudspeaker when integrated with talk back system - Different microphone options:

• without microphone (IMCOS-7011-V2-0)

• handheld microphone (IMCOS-7011-V2-1L)

• gooseneck microphone (IMCOS-7011-V2-2L) - Multiple remote control panels can be controlled by a proprietary network RS 485 data interface to the main unit

- Local loudspeaker bypass to avoid audio feedback

- Redundant power lines

DESCRIPTION

IMCOS-7011-V2 is a remote control panel, designed for announcements, pre recorded messages broadcast through the public address as well as talk back main station.

Designed to meet and exceed the requirements of ABS, BV, CCS, DNV-GL, LR, RINA, Norsok and UKOOA/PFEER.

Material Aluminium – black colour RAL 9005

Mounting Desk mounting

Wiring Terminal strip on the back

Cable glands 1 x PG16 (5/8”) – 1 x PG21 (3/4”) standard

Number and size can be configured according to the specific use of

the box

Dimensions Height 290 mm, width 215 mm, depth 150 mm

Weight 3,2 Kg

Contact EHRE(Shanghai) to discuss your unique interior communications requirements.

LESER LNG and LPG make gas mobile

Demand for the compressed form of natural gas and petroleum gas is growing steadily and is expected to account for one third of global gas consumption in the medium term. Investments must pay off in the short term in order to remain profitable despite ever shorter supply contracts and trading on energy exchanges.

The shortening and flexibilization of supply chains by combining production and processing steps, e.g. on FLNGs (Floating Liquefied Natural Gas) or FSRUs (Floating Storage and Regasification), make this possible. However, the requirements for such projects are complex. Your supplier must be able to master this complexity of projects and the technical challenges.

LESER ensures reliable functioning and tightness of your safety valves even at cryogenic temperatures of -164°C and pressures up to 155 bar, which are necessary for the processing and transport of LNG. No matter which LNG application, onshore, offshore or even mobile, LESER has the right solution and approval for you.

The LESER Advantage

The requirements for safety valves are manifold from conveying, liquefaction, transport, regasification and subsequent distribution. The LESER product range always offers the suitable product with the Types 526, 441, 459 and the Cryo-POSV optimized for LNG/LPG applications.

Thanks to the modern production technology Nanothightness, LESER achieves a 50% higher metallic tightness than API 527 requires. This still reliably meets the requirements of API 527 even at cryogenic temperatures and can be verified on LESER’s own cryo test bench.

LESER’s extensive network of sales engineers and its own project processing center will help you to deliver gas faster, both for technical requirements and in the execution of your project.

Case Study

LESER LNG POSVs support high plant efficiency in liquefaction process

The Challenge

The liquefaction process must be designed efficiently so that the LNG can be offered economically. The necessary cryogenic media temperatures of -161 to -164 °C represent a challenge for the technical design of the individual components in the plant. This also applies in particular to the safety valves, which must function reliably as the final protection in the event of overpressure, even at the cryogenic process and Russian ambient temperatures.

Linde expected its suppliers to provide a reliable and punctual delivery in addition to solving the technical requirements.

Why did the customer choose LESER products?

LESER valves meet all requirements for use in natural gas liquefaction plants and offer a complete product range. The valves are designed in the low-maintenance “Durable Design” and can be adapted to the plants by various options.

Industry/Application:

LNG / natural gas liquefaction plant

LESER Solution:

POSV, Compact Performance, API

Customer since:

For more than 20 years

Quantity of Valves Supplied:

288 safety valves: 6 Type 811, 47 Type 459 and 235 Type 526

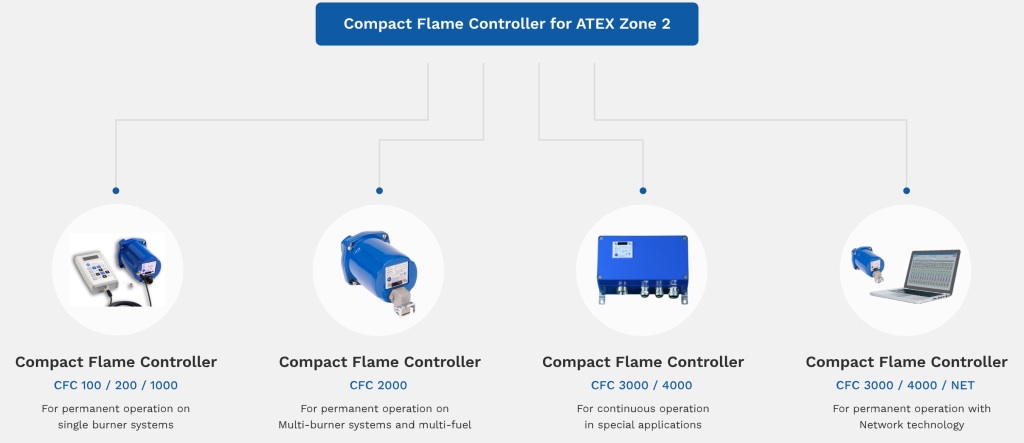

Flamonitec Compact Flame Controller for ATEX Zone 2

Since BFI Automation launched the first compact flame controller for continuous operation in 1990, we have been working continuously on optimising this technology. The compact flame controller combine the former system consisting of sensor and amplifier in one housing. The compact flame controller is connected directly to the burner control or control system. This eliminates the need for additional space for the amplifier/monitor and the associated cabling. Compact flame controller are therefore not only suitable for new equipment, but especially for retrofits or conversions.

Through various sensors and expansion stages, BFI Automation offers the right and most suitable compact flame controller for every area of application.

Whether single burners with different fuels or multi-burner systems as in large power plants with bus systems, we always offer the right solution.

Almost all compact flame controller can be supplied with fibre optic technology and/or for explosion protection in zone 1 or 2.

- IECEx-Certificate

- ATEX Zone 2

- IECEx-QAR

- High availability

- Technical support

- Maintenance free

- Coverage of different spectral ranges

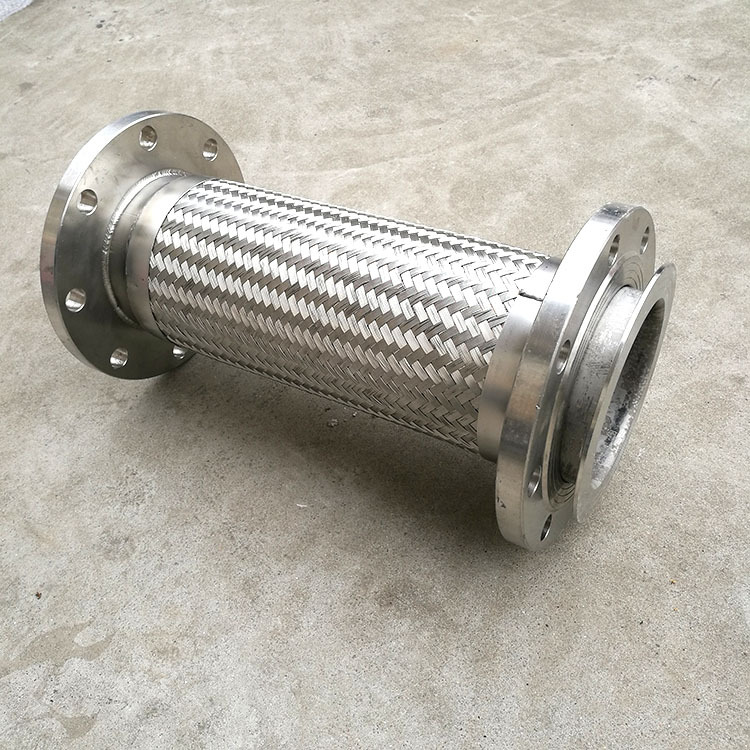

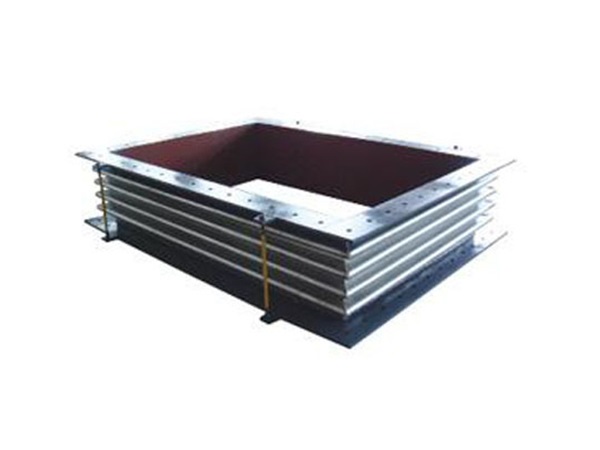

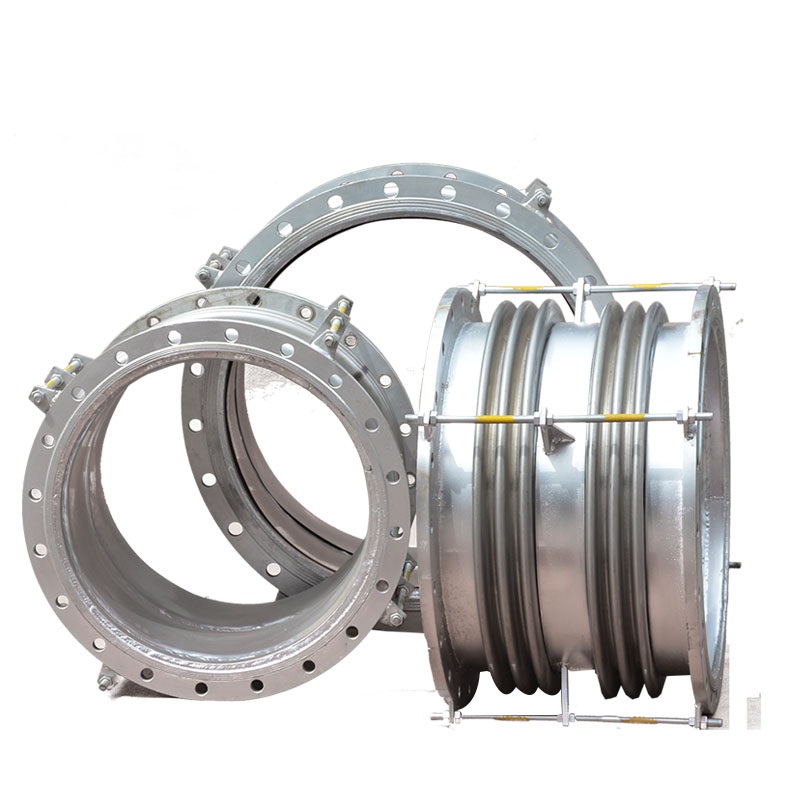

Customized Metal Hose and Compensator

Metal corrugated compensator is a compensation element. The effective expansion and deformation of the working body bellows is used to absorb the dimensional changes caused by thermal expansion and contraction of pipelines, conduits, containers, etc., or to compensate for the axial, lateral and angular displacement of pipelines, conduits, containers, etc. It can also be used for noise and vibration reduction. It is widely used in modern industry.

Under normal circumstances, the material selected for bellows should meet the following conditions:

- High elastic limit, tensile strength and fatigue strength to ensure the normal operation of bellows.

- Good plasticity, convenient for the processing and molding of bellows, and can obtain sufficient hardness and strength through subsequent treatment processes (cold work hardening, heat treatment, etc.).

- Good corrosion resistance, to meet the working requirements of bellows in different environments.

- Good welding performance, to meet the welding process requirements of bellows in the production process.

Our company specializes in the production of metal bellows compensator, non-calibrated, length customization, welcome to consult.

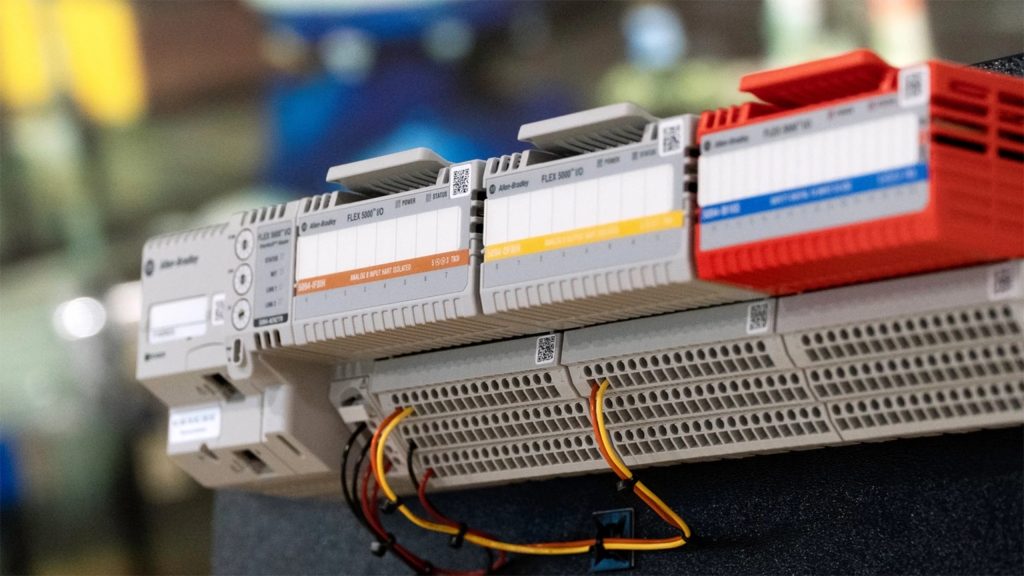

ROCKWELL Allen Bradley Input/Output (I/O) Modules

Gain Operational Efficiency with a Wide Range of I/O Solutions

Whether your application requires the I/O to operate in harsh environments or hazardous areas, mount on a machine, or act as a local I/O for your programmable controller or more, pick what you need from us.

Deliver a smart, productive, and secure Integrated Architecture® system in discrete, process, motion, and safety applications with our integrated control and safety solutions built with controllers and I/O at its core. Start your I/O selection here.

JOKWANG JSV-FF100 Safety Valve

JSV-FF100

(Conventional/Balanced Bellows Type)

It is used as a safety relief valve in the piping of gauging devices and various pressurized containers at oil and gas plants and petrochemical plants.

This product has been designed according to the standards of API STD 526. It has acquired certification for capacity and quality from the ASME (“UV” stamp). Made of various materials, it can be used in high temperatures, high pressures and for corrosive liquids. It has acquired certification from the Occupational Safety & Health Agency and The Korea Gas Safety Corporation. The standards of API STD 527 for leakage is applied.

Product specification

| FORMAT | CERTIFICATION | SIZE | OFRICE AREA | ORIFICE DIAMETER | CORRECT PRESSURE TO BE APPLIED | HOW TO CONNECT THE ITEM | CORRECT TEMPE RATURE TO BE APPLIED | CRITERION FOR LEAKAGE |

|---|---|---|---|---|---|---|---|---|

| Conventional & Bellows Full Bore Type | UV Stemp Occupational Safety & Health Agency, Korea Gas Safety Corporation | 3/4″ x 1″ ~ 14″ x 18″ | D(70.96㎡)~Y(49082.5㎡) / D(0.11in²) ~ Y(76.078in²) | D(9.5mm)~Y(245.0mm) / D(0.374in) ~ Y(9.842in) | 0.1~41.36MPa (1.05~421.8kgf/cm²) | Flanged | -196~538°C | API Standard 527 |

ECONOSTO Safety Valves

Econosto is a supplier of high-quality valves, safety devices, regulators, level gauges and steam traps that meet the demands of shipyards, hydraulic engineering, industry, power plants and many others. We’re a multi-industry company specialising in importing and selling industrial and hydraulic engineering products both in Finland and in the export market.

Our product range includes a large selection of quality-certified valves and regulators for various purposes. Thanks to our versatile product range and strong competence, our customer base includes representatives from a variety of industrial fields. Build a combination of our products to suit your company’s specific needs – we’re happy to help you find the right solution.

Gitiesse IMCOS

Gitiesse IMCOS (Integrated Multi-Media Communication System) is an umbrella digital network that integrates all the internal communication and distribution of alarms and signals onboard a ship.

Who is Gitiesse?

Gitiesse is an Italian based company. In 1979, it was established as a Trading company by the technical company Girotecnica. In 1985, the two companies merged. In 1994, Gitiesse designed the first IMCOS system in the world. Since then, over 2000 systems have been installed worldwide.

IMCOS‘s “open architecture” modular design, enables versatility and customization to meet the unique requirements of a vessel, regardless of size or electronics configuration; from coastal craft to supertankers. IMCOS installations include major passenger vessels, super-yachts, merchant & naval ships, cargo ships, oil and gas maritime applications and more.

Typical IMCOS Basic “Section” Configuration:

• General & Fire Alarm • Public Address • Sound-Powered Telephone • Ship Service Intercoms • Automatic Telephones • Radio & TV Signal Distribution Network • Surveillance CCTV • Engine Room Signal Columns • Computer Data Network • Optional: music channels, automatic messaging, passenger info, etc.

IMCOS systems are certified ISO 9001/2000 and type approved by the major Ship Classification Societies.

Contact EHRE(Shanghai) to discuss your unique interior communications requirements.

Crowcon Multi-function display pump-suction gas detector Xgard

The Xgard Display Series gas detectors are specifically designed to protect operators from potential personal injuries in complex operating conditions. It can detect the dangers caused by toxic gases, combustible gases and hypoxia, and remind operators to take immediate countermeasures.

The Xgard display series is available in different sensor type configurations to meet different inspection needs on the job site. The pump suction type is optional, and the flameproof suction pump pumps the gas to the gas detector from the far end (within 100m) for detection and alarm, or draws gas from the periphery of the detector to speed up the reaction speed.

Features

* Flexible installation allows for wall-mounting or ceiling-mounting without the need for additional brackets

* Guided operation menu, simple and easy to use

* Non-intrusive magnetic rod calibration without the need to open the lid on site

* Bright OLED display for low temperature environments to minus 40°C applications

* Integrated sound and light alarm, 110dB@10cm (optional)

* Different types, multiple sensor configurations, can detect 100 gases

* Rich output signals, in addition to 4-20mA current loop signal, provide up to 3 relay outputs

* MODBUS、HART(optional)

* Sensor type: catalytic combustion, electrochemistry, PID (VOC detection)

* Protection class: IP65,IP66

* Probe sensor lifetime: Xgard gas: 2-3 years